A lean handover is a process that aims to minimize waste and optimize efficiency in the transfer of a construction project from the construction team to the facility management team. It aims to eliminate the significant waste that exists in common turnover workflows today.

Some background

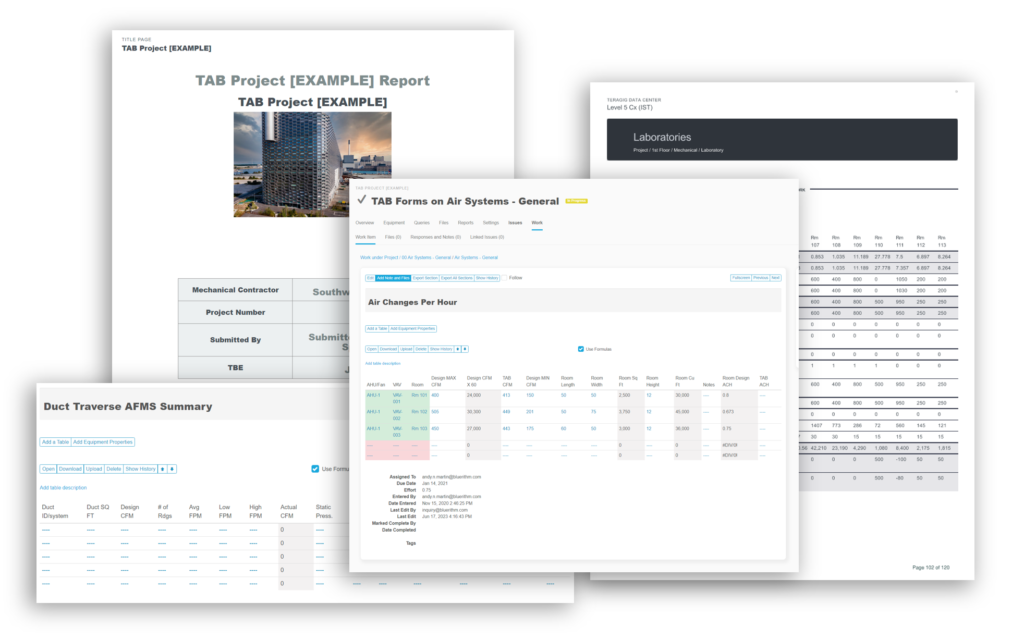

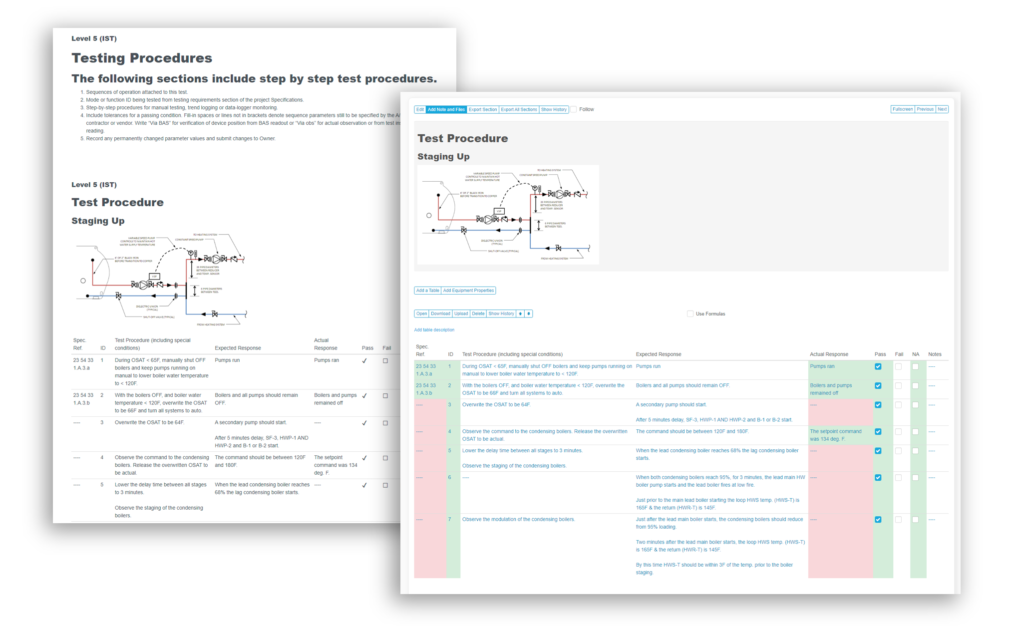

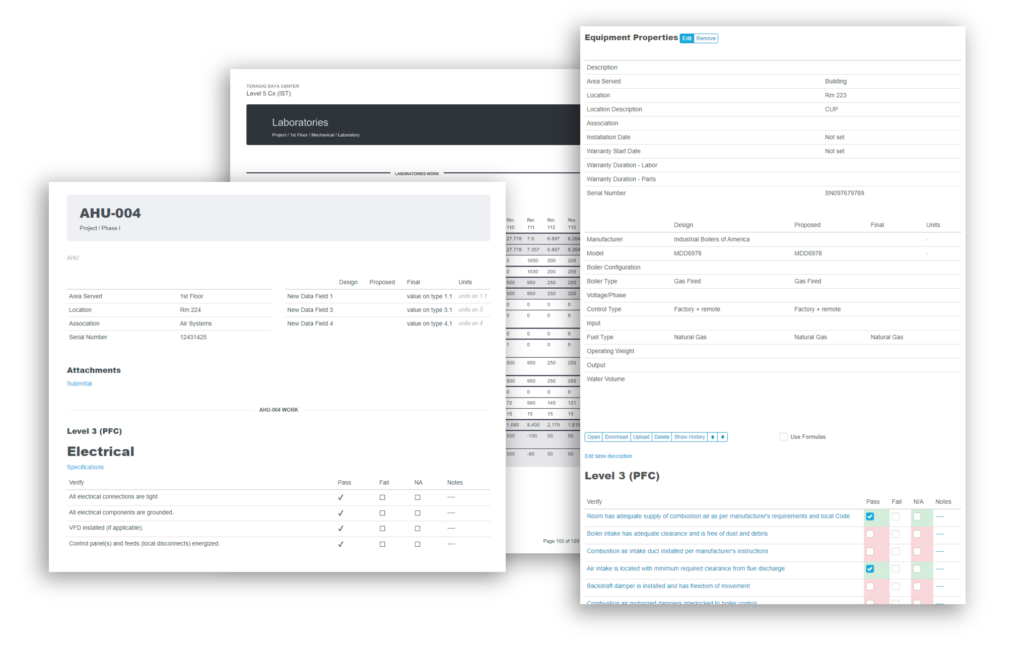

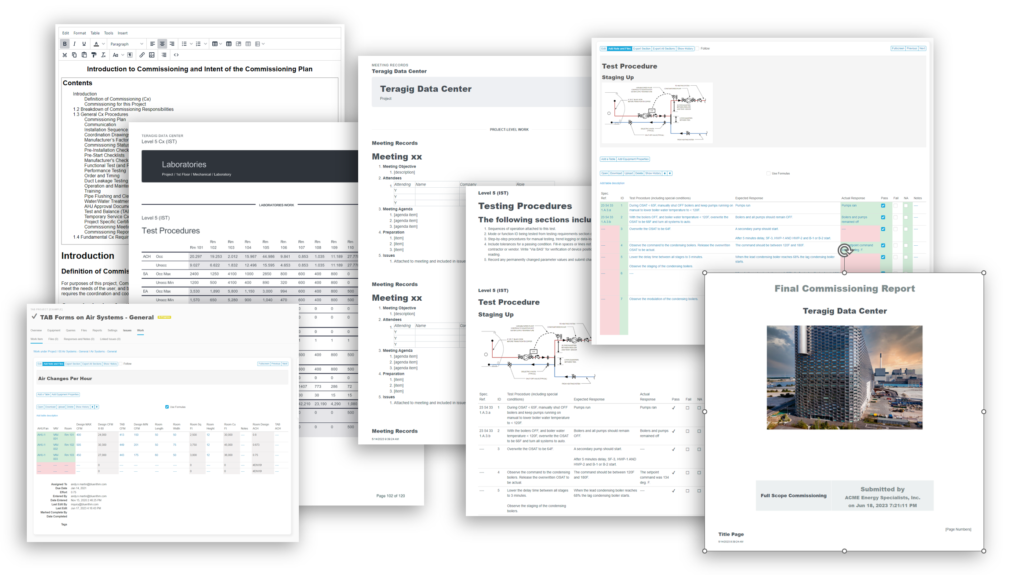

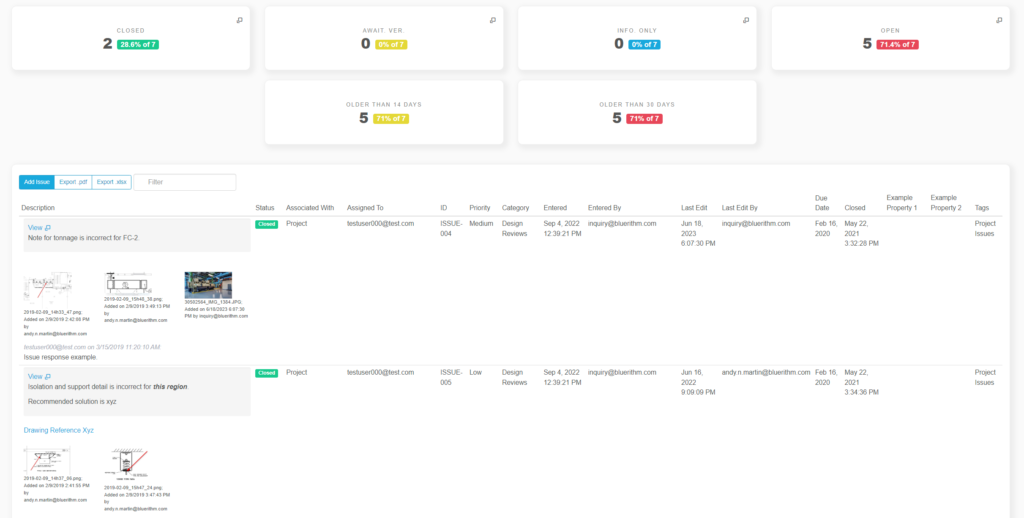

Traditionally, the handover (also known as the turnover) process has been a lengthy and cumbersome one, involving the exchange of large amounts of documentation and the completion of many detailed checklists, asset data, test results, operation and maintenance data, warranty information, and much more. This can be time-consuming and prone to errors, because there is a lack of standardization in the process.

Turnover packages are often difficult or impossible to use.

Even when the data is “digital”

- CD-ROM

- Thumbdrives

- Generic cloud file storage

While better than paper copies, none of these sources are easy to use, search, or query

- More productivity loss for operators and future design teams

- Errors in replacement parts and inefficient maintenance practices

- Energy audits, calcs may require manual collection of equipment data

Every construction project requires a similar variation of data at handover, yet on each project the workflows and process are often reinvented, introducing staggering inefficiencies. This is one of many examples of how our industry remains the least efficient in the world.

A lean handover, on the other hand, aims to streamline this process by focusing on the essentials and eliminating unnecessary steps. A related and somewhat interchangeable term is digital turnover. One of the pioneers of the lean handover is Bill East of Prairie Sky Consulting.

One of the key benefits of a lean handover is the reduction of errors and rework. By focusing on the most important aspects of the handover process, the risk of mistakes and the need for corrective action is minimized. This can save time and money, as well as improve the overall quality of the project.

How to deliver a Lean Handover

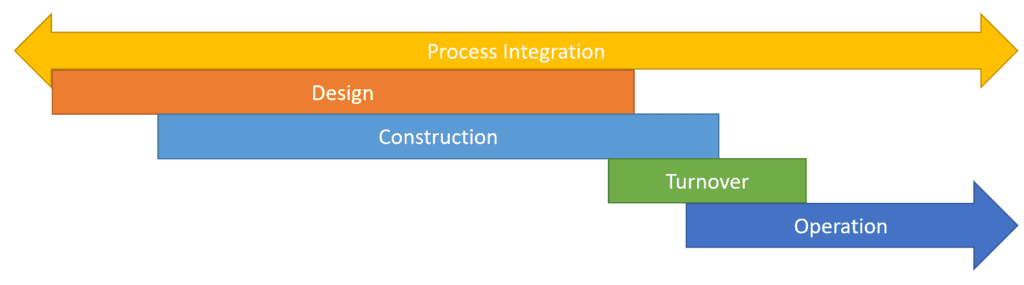

When operating in traditional silos of owners, design teams, and contractors, which is an inherent to the design-bid-build model, a lean handover is more challenging to do well, or at all. A successful lean handover requires willful cooperation from all parties beginning in the early design phase.

An integrated project delivery model is best suited for lean handover, because it has inherently less silos and facilitates the higher levels of cooperation needed for a successful lean handover.

All stakeholders will need to be involved in the process, and tight cooperation ensures that data is only entered once. Project data can flow through various tools and applications used on the project without additional manual data entry.

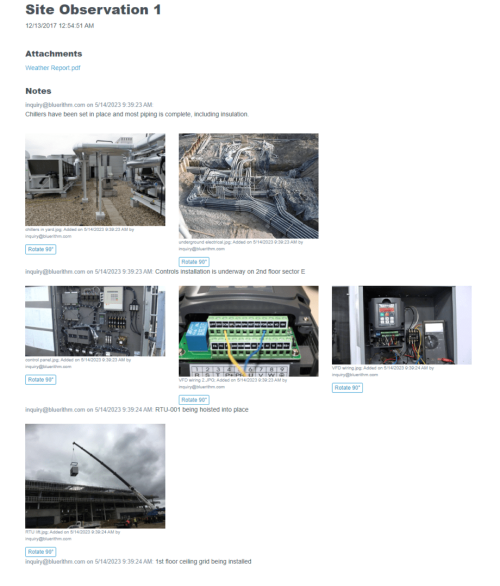

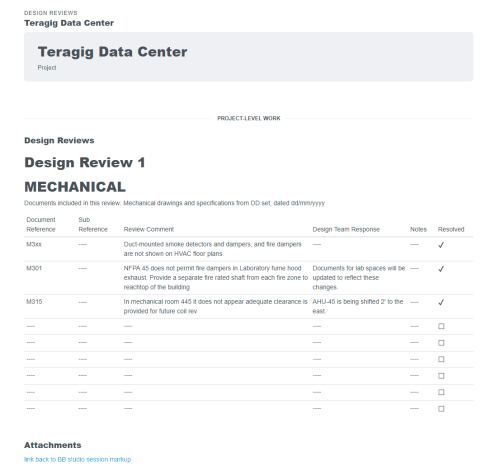

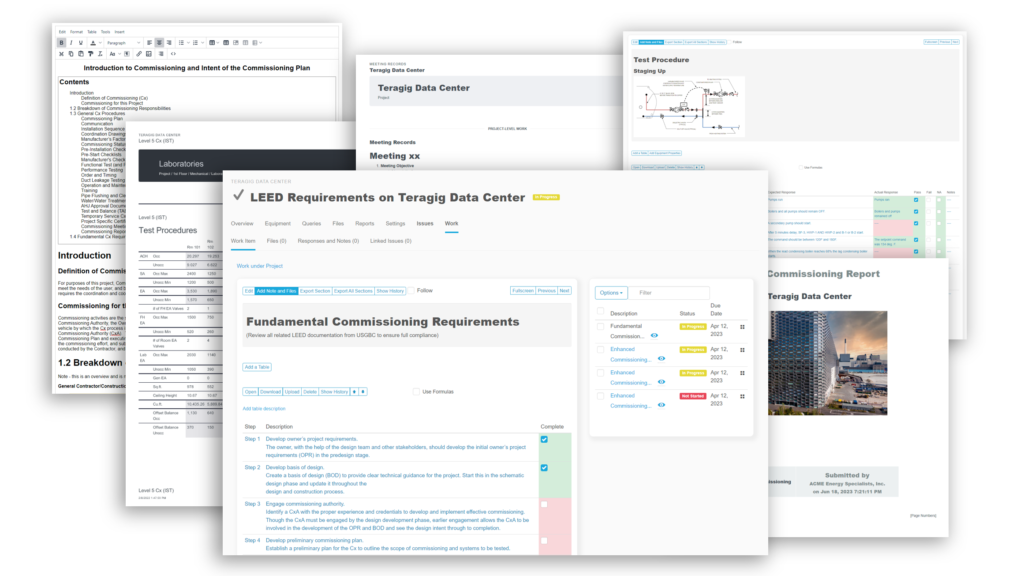

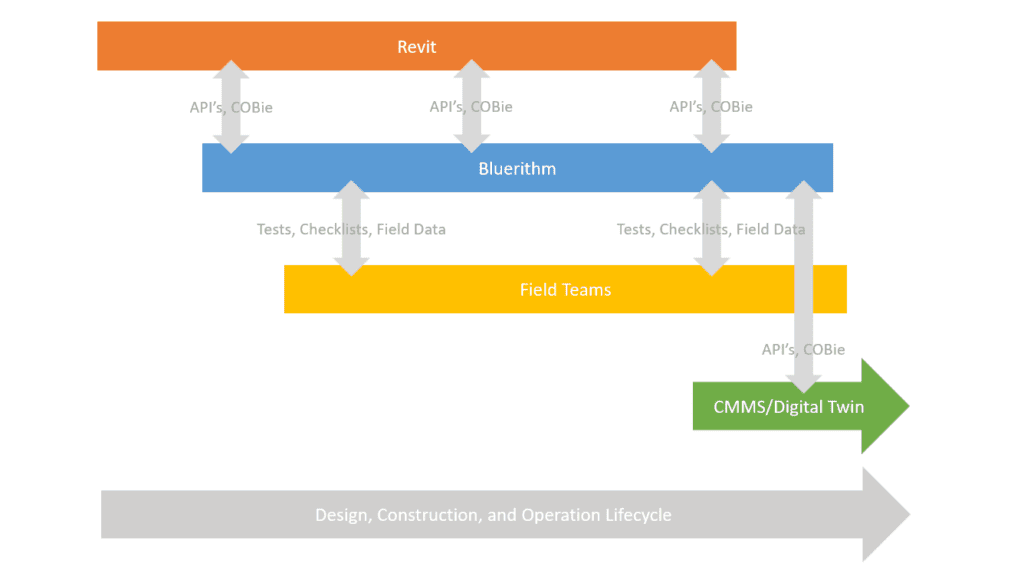

For example, asset properties like location data, capacities, ratings, etc. is normally defined during design, by the design team. There’s no need for the contractor design teams, field technicians, commissioning firms, etc. to ever enter that same data into any system again. It’s quite easy to have this data automatically flow through the various applications (e.g. Revit, field tools, commissioning tools, and finally to an owner’s maintenance management platform) by using a common data environment approach with a platform like Bluerithm. The common data environment is where all of the handover data is aggregated in real-time, throughout the project. So while a motor electrical rating might be defined during early design, it’s serial number needs to be verified and possibly entered in the field by a technician. Using tools like Bluerithm streamlines this process and automatically aggregates data throughout the entire project.

Leveraging open standards like COBie or native integrations between platforms can further improve quality, reduce errors, and streamline the process.

Summary

A lean handover is a valuable tool for improving the efficiency of the construction process. By focusing on eliminating waste, it helps ensure that the facility is ready for operation and maintenance, and sets the stage for a successful, maintainable, and sustainable facility that fulfills the owner’s project requirements.