Guide to Implementing Digital Twins

Table of Contents

What Are Digital Twins?

A digital twin is a virtual replica of a physical building or industrial project in the real world and enables virtual interaction with the asset. Digital twin technology provides an immersive, photorealistic 3D exploration of space that enables collaboration among multiple stakeholders. This data-driven process enables teams to monitor physical assets, make better decisions, help you maintain a building, and streamline operations.

During construction, a digital twin can serve as a model of progress. As the building is completed, a digital twin can be updated so that teams are always up-to-date on the status of the project. Immersive BIM 3D models allow team members to virtually “visit” a space, cutting down on costly site visits.

Benefits of Digital Twins

1. Reduced Costs

- A virtual replica of your building or industrial project can help you predict maintenance needs, reduce risks of equipment downtime, and optimize business operations, ultimately reducing overall costs.

2. Informed Decisions

- Digital twins allow you to simulate different scenarios and make informed decisions before implementing changes in the real world, minimizing risks and avoiding possible failures.

3. Use for Future Optimization Projects

- The insights digital twins provide can help support ongoing structural enhancements and can be used for future projects.

4. Streamlined Facility Management

- Digital twins can pinpoint problem areas and share necessary information with technicians to solve the problems. They even help to keep track of who should be billed for the work.

5. Improved Efficiences

- Sensors can be used to analyze how a facility is being used and then changes can be made to increase efficiencies.

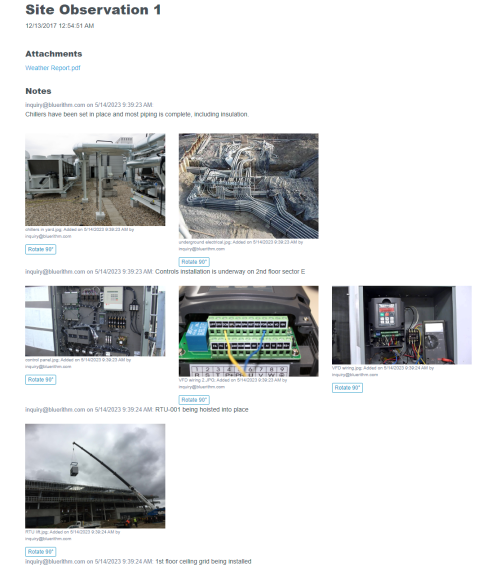

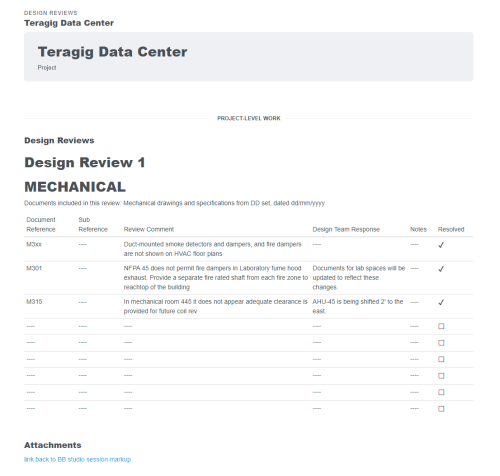

6. Easier Communication With Stakeholders During Construction

- Stakeholders can stay up-to-date on the latest advancements in the construction process and red-flag any immediate concerns.

Preparing for the Creation of Digital Twins

Without proper preparation, you may encounter challenges when implementing digital twins. It is important to take your time to ensure you have adequately planned for what is needed for implementation, including computational resources and infrastructure, data attributes you need to collect, how you will model data, the kind of governance and oversight required to ensure the digital twin is used effectively, and how the digital twin will be used to support decision making.

Data Center Infrastructure

Massive influxes of data can be generated by digital twins, so you should ensure your data center is capable of processing that data. Your data center infrastructure should also be secure. Data encryption, firewalls, and access controls would be used to protect sensitive information from unauthorized access.

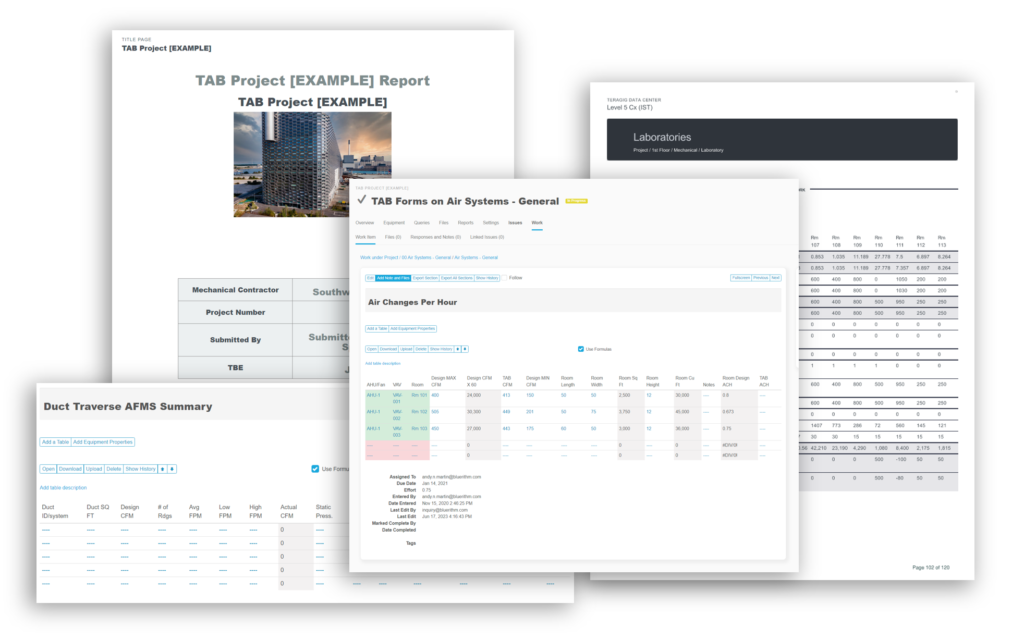

Common Data Environment

A common data environment (CDE) is a centralized platform that allows all stakeholders to access, input, organize, integrate, and share data in a standardized format. It is the single source of truth for data related to the project.

Investment

Digital twins can require significant initial investments in infrastructure and personnel. You should also consider in advance the ongoing costs of operating and maintaining the digital twin. Consider the business rationale for creating the digital twin and estimate the financial benefits.

Data Collection

Data preparedness is a crucial step for successful digital twin implementation. You should identify and collect the data required to replicate a physical system. Automated data collection and well organized CDE’s can reduce the risks associated with human errors, both during the design and engineering process and after implementation. Real-world information about the building or industrial project is gathered and combined to create digital twins. 3D laser scanners, drones, IoT sensors, cameras, manual data entry and verification, and other methods are typically used to collect static data and send information back to the twin in real-time. The digital twin learns from these multiple sources of information and automatically updates to reflect changes to its real counterpart. Information can include physical orientation, stress loads, leaking pipes, etc. This information helps teams track milestones and gain an understanding of a project’s life cycle.

Software

Physical modeling capabilities to simulate the building or industrial project are needed. Digital twins are typically accessed through specialized software, which give project stakeholders a single source of truth for digital twin storage and sharing.

Rules and Regulations

It is important to familiarize yourself with local laws and regulations before using digital twins on a construction site.

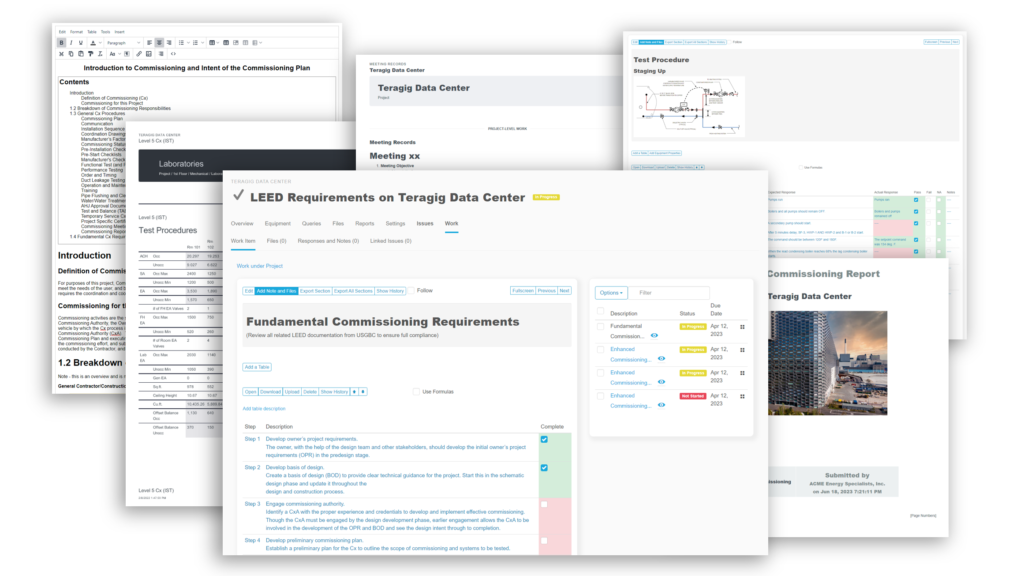

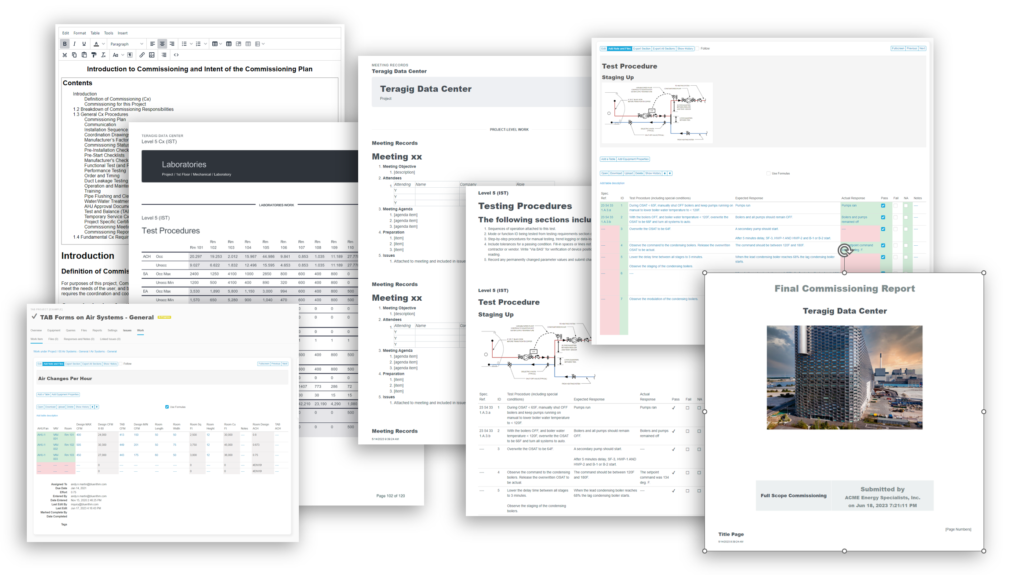

Bluerithm Demo

Play Video about Bluerithm demo

Move your Excel-based processes to the cloud

Start saving time and money today