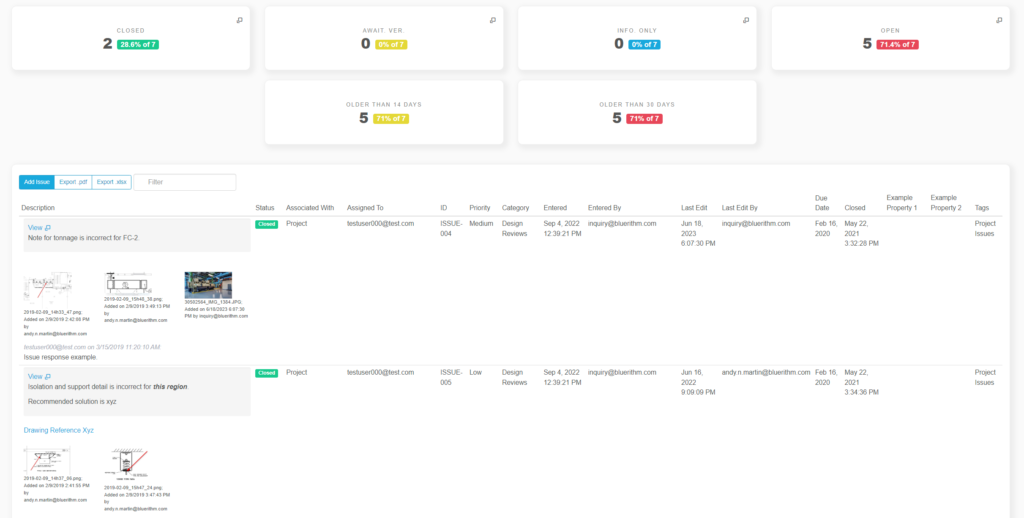

Bluerithm’s robust, cloud-based platform can help you create a detailed collection of all commissioning tests and procedures and create a handover package!

Guide to Industrial Project Commissioning

Solution:

Table of Contents

3 Items Needed for Industrial Project Commissioning:

- Roadmap

- Team

- Documentation

Create a Roadmap

Industrial project commissioning should start with a commissioning plan in order to establish a framework for handling and managing commissioning on the project. This serves as a project roadmap and identifies all parties involved, roles and responsibilities, and documentation that is required.

Commissioning planning starts with a schedule and process systemization. For example, process systemization can take piping and instrumentation diagrams and identify sub-systems that can be broken out and prioritized based on a sequence of events to start up the facility. The commissioning engineer then works with the contractor to prioritize construction completion to meet the systemized startup sequence.

Select the Team

The scope of commissioning differs from industrial project to industrial project and client to client and the proper team must be selected to carry out the commissioning activities. For example, a chemical plant commissioning team should include a chemical process engineer, a mechanical engineer, and an electrical, controls, and instrumentation engineer. The chemical process engineer would help with understanding processes as they are designed, the mechanical engineer would be responsible for the full check and verification of all mechanical equipment in the field, and the electrical, controls, and instrumentation engineer would handle all of the electrical power distribution systems and instrumentation testing and documentation.

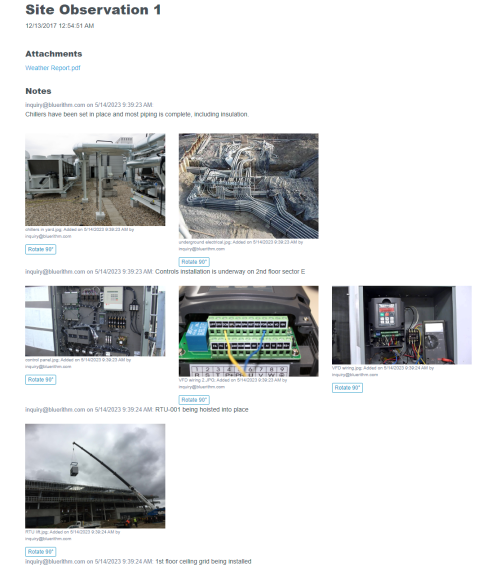

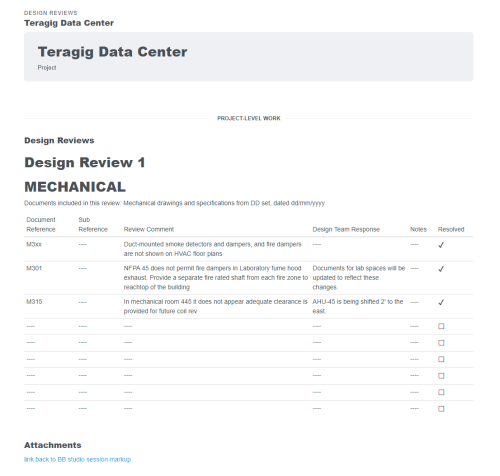

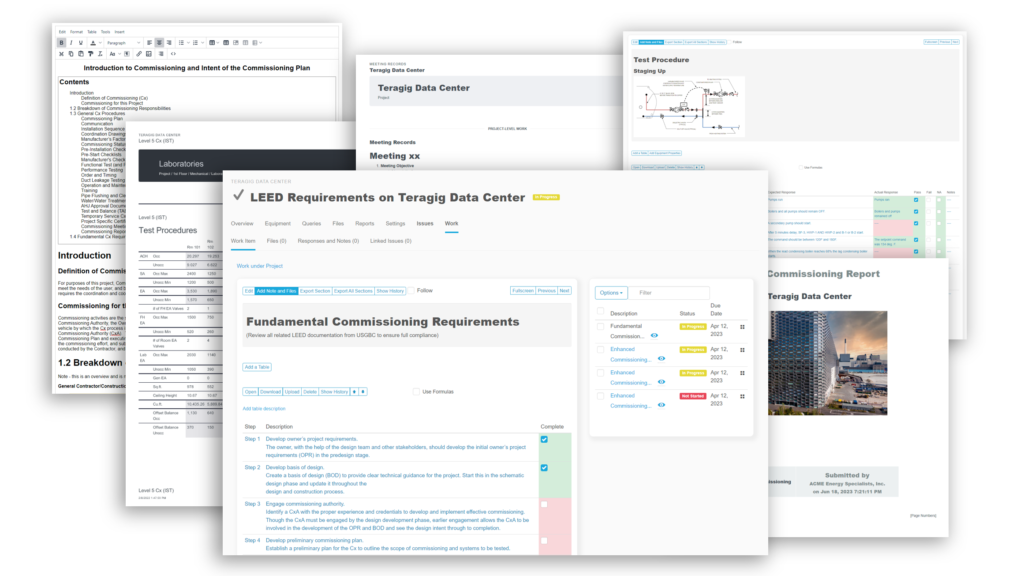

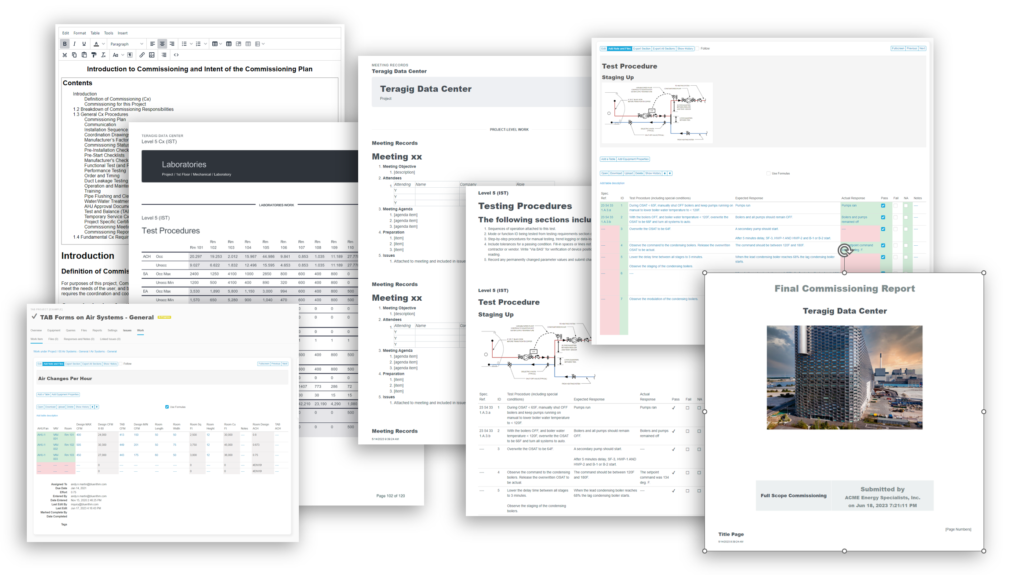

Create Documentation

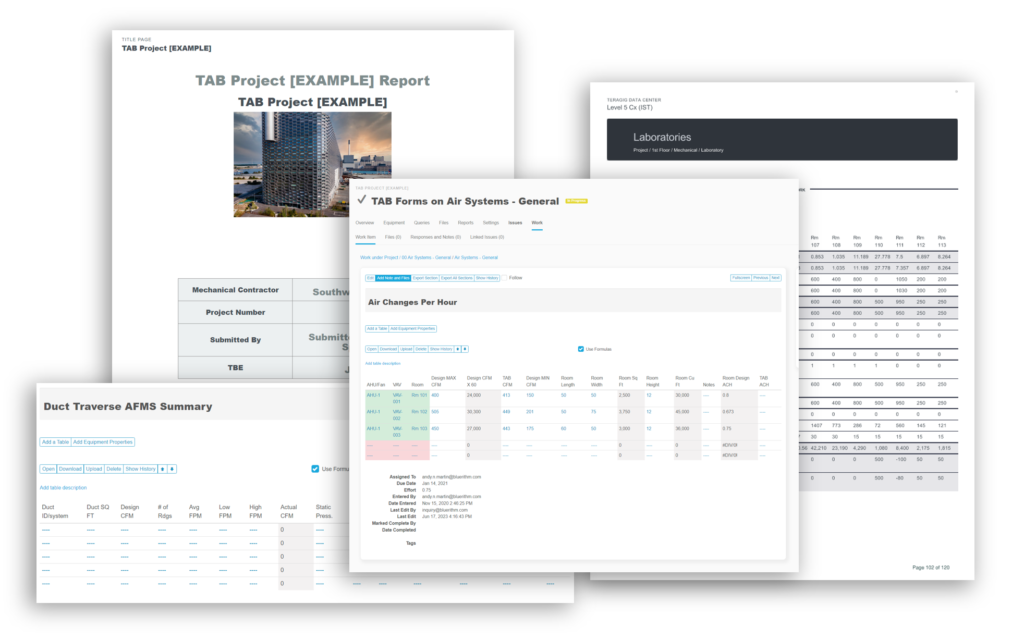

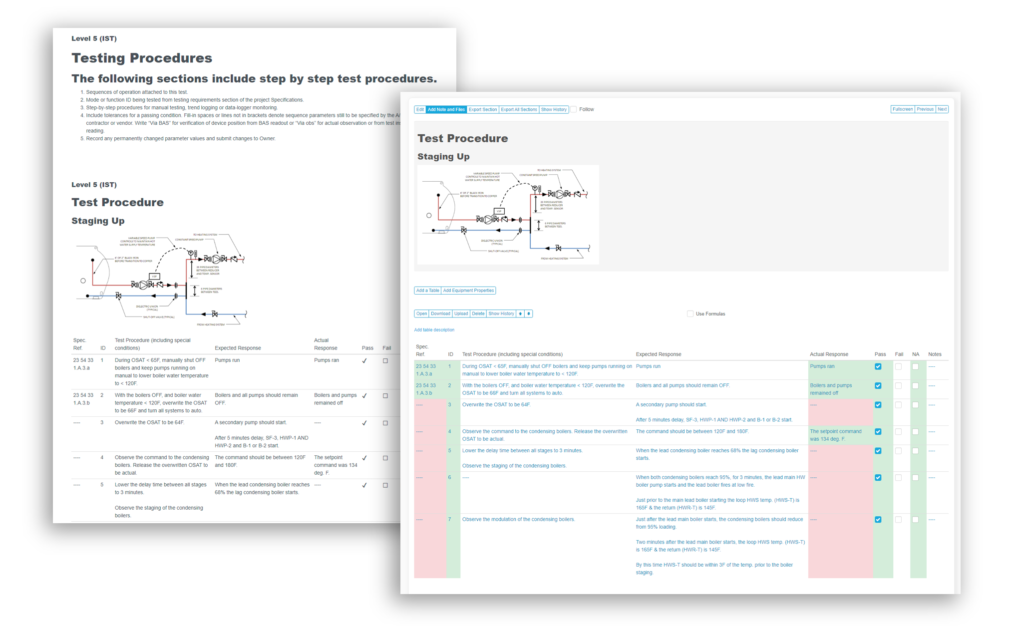

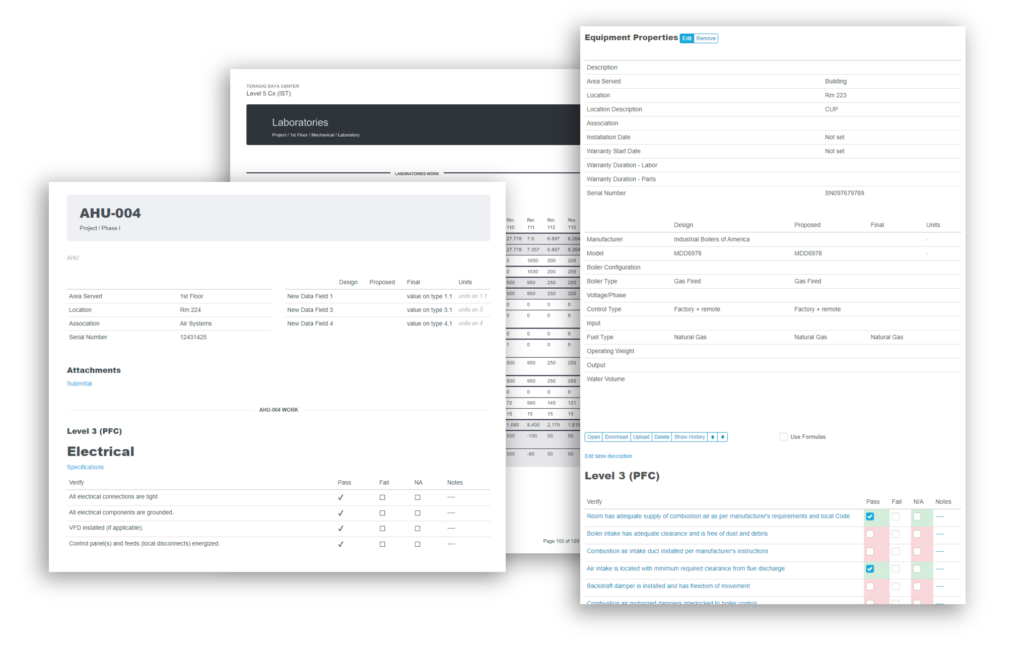

It is extremely important to have a detailed collection of all commissioning tests and procedures to verify that everything was done to the correct standards and practices. All final approvals and sign-offs for cleaning, testing, inspection, and acceptance flows through the commissioning team. All documents are recorded and compiled into a handover package. When handover occurs, it serves as the sign-off on responsibility from the contractor to the owner, who is then responsible for operating each system.

3 Stages of Industrial Project Commissioning:

- Pre-Commissioning

- Commissioning

- Startup

Pre-Commissioning Stage for Industrial Projects

The activities that are carried out during this stage occur during the final stages of construction and include:

- Pre-functional test (PFT) inspections

- End-of-construction punch lists and check sheets

- Factory and site acceptance testing of control systems

- Instrument loop checks

Commissioning Stage for Industrial Projects

This is sometimes referred to as “cold” commissioning. For a chemical plant, this stage would include running and testing the process without adding the chemicals or hazardous materials. For building commissioning systems, this stage would include pre-functional testing of complete building systems, pre-commissioning focusing on equipment, and commissioning focusing on the system.

The owner typically executes the cold commissioning with support from the commissioning team. The commissioning team supports the owner with the planning and scheduling of activities, requirements for support from contractors, and engineering calculations for various commissioning tests. Standard tests for a chemical plant that may require engineering support and calculations could include water system flushing, compressed air blows, temporary support of piping for testing, and steam blows.

Commissioning can be executed on individual systems, groups of systems, or partial systems. The commissioning team may be required to modify system commissioning as systems reach construction completion because the commissioning timeline is a function of construction progress.

Startup Stage for Industrial Projects

The plant is brought into operation by the owner during this stage. The commissioning team provides engineering support as required by the owner during startup. Successful commissioning will generate site-specific knowledge that can be used by the commissioning team to assist in the startup. Common support functions include:

- Operator systems training

- Process systems troubleshooting

- Lockout-tagout practices

- Pre-startup safety review participation

See How Much Bluerithm Can Save You on Your Industrial Commissioning Projects Using These Calculators

Bluerithm Demo

Play Video about Bluerithm demo

How to Set Up a Bluerithm Project

Play Video about How to Set Up a Bluerithm Project

Move your Excel-based processes to the cloud

Start saving time and money today