Transcript

Andrew Martin: [00:00:00] Good afternoon, Chris. How are you doing today?

Christopher Fasano: I’m good, Andrew. How are you?

Andrew Martin: Great. Great. Where about in the world are you calling in from today?

Christopher Fasano: Present moment. I am in St. Louis, Missouri. That is where our company’s headquarters is located. That’s where I do most of my work out of, but as I am frequently all over.

Andrew Martin: That’s right.

That’s good. Good and bad aspects of that.

Christopher Fasano: Mostly good. Mostly good.

Andrew Martin: Yep. Good deal. What are some of the interesting places you’ve been to recently?

Christopher Fasano: Oh, let’s see. Recently we’re doing a lot of work up in New York in the tri state area. San Francisco, San Diego, Houston. We’re kicking some stuff off in Atlanta, Georgia.

We’re all over, but those are probably the highlights as of recently.

Andrew Martin: Gotcha. Gotcha. And I suppose while you can, you try to travel around with the weather and land where it’s nice and avoid the places it’s not.

Christopher Fasano: We’ve actually got some stuff in Hawaii, but as you [00:01:00] can imagine, everybody tries and jockeys for position to manage the Hawaii projects.

Andrew Martin: I can imagine. I can imagine that. Let’s jump into things here. It’s great to be talking today. Today there’s a lot of folks interested in airports and airport systems. It’s not something that, a lot of people run into in their day-to-day work. So having somebody like yourself come in and just talk about your experience, what it’s like, some of the complexities and uniqueness of airport systems and just airport projects and construction in general, I think is a really fascinating topic to people to some of these projects are just so large and complicated and long in duration.

It’s just they’re unique in a lot of ways. So, I’m really looking forward to hearing from you about some of what we’re going to talk about today. But, before we jump into anything specific, do you want to just give, an overview of kind of your role at the company you work with, Faith Group, and what you guys focus on and what the [00:02:00] progression was in your career that got you to this point and involved in projects like this?

Christopher Fasano: Sure. Yeah. So as a firm for Faith Group, the best way we find to describe ourselves as an engineering and technology consulting firm. What that means is we do a lot of different things. We focus around how we can best serve the challenges our clients face in any particular engineering or technology sector.

If I have to pick an area that we primarily specialize in, it would probably mostly be aviation security, telecommunications, IT network, infrastructure, and architecture. But as a firm, we have, we service multiple markets do everything from MEP design to.

Commissioning consulting, concept of operations, et cetera. So, we provide a multitude of different services within the engineering and technology field. Me, myself I got started in the power sector. Building cogeneration power plants. It’s where [00:03:00] my affinity for complexity started in these cogeneration and microgrid setups, you have a lot of different systems all meant to operate in concert oftentimes under different projects, different contractors, sometimes different departments and sectors of the industry and getting them all to work together piqued my interest in the complexity side, which quickly got me moved over into the commissioning sector a few companies ago is where I started my commissioning journey, mostly around, the stuff that was known, MEP, lead focused commissioning things of that nature, but quickly found a very large gap in the industry for systems that live outside of the regulatory commissioning world specialty systems, EV network, cyber security, Wi-Fi, telecommunications, security, things like that.

That in most cases required similar forms of commissioning or even more intense commissioning due to the complexity and nature of the system. So, when I started at faith group this was my first opportunity as the commissioning manager, I managed our entire [00:04:00] commissioning service.

So, it was an opportunity for me to embrace some of the gaps that we saw in the industry. And as a firm, we sell ourselves as people who can commission anything we can design or consult on. Division 22, 23, 26, 27, 28 as well. What we focus on is what we call MSI, Master Systems Integration.

So, all the network, IT infrastructure associated with, connecting these elements to the localized network is what we’ve hit the ground running with and what we’re providing, especially for our aviation clients.

Andrew Martin: Awesome. I’m sure that resonates with a lot of people and it does myself as well.

Just being attracted to the scale and the complexity of some of these projects and why we end up where we do. Some people thrive in that sort of environment and in these sorts of projects. And it’s just, interesting and fulfilling to be involved in something, projects like this, whether it’s the power plants, obviously those are hugely [00:05:00] impactful projects, airports or whatever these large scale projects that we’re all in and the technology systems and just systems in general, bringing the, bringing these plants or facilities and operations to life and just having it dialed in is just immensely satisfying after, years of construction and suffering sometimes to get to that point.

It’s just very satisfying. Cool. So, thanks for that. So, to jump in a little bit to the airport systems in general. Can you talk a little bit about some of these specialty systems and the technology that exists in airports that doesn’t exist in other types of buildings. Especially commercial buildings or even plants. Everything from security to the operational systems and the AV systems and the backbone that kind of ties all these things together.

Christopher Fasano: Yeah, absolutely. I think one of the unique aspects within the aviation [00:06:00] industry, airports in particular, is there are a lot of specialty systems that are unique to, to an airport facility, right? You have all of your baggage handling systems, you have all of your regulatory systems associated with, Elements like TSA, you have information display systems specifically for flight information, air traffic information, etc.

All these things that are wholly unique to the aviation industry and airports in particular, right? So that is one unique aspect where you can’t go. It’s hard to stretch outside of the industry itself to find case studies or information on systems that other facilities simply aren’t utilizing.

It makes the world within the aviation industry somewhat smaller in that sense. It makes individuals within that industry become highly specialized in those systems. So, for instance, you can be up against some of the challenges with new systems. One of the big ones is self bag drop systems now where [00:07:00] aviation clients are trying to implement these self bag drop systems, which have to be integrated with a multitude of other systems, passenger processing, security, et cetera.

And all this stuff is new and nobody has done it before. And you’ve got, manufacturers and service providers that are trying to implement these new systems. Large projects with deadlines, they can’t move, you have to go live dates, et cetera. Within the aviation industry, there are a lot of incredibly unique systems that are specific only to that industry.

So, when you look at commissioning, you have to understand as a consultant, where to go to find that information so that you can best service your clients in how these specialty systems work. And within the industry, we see unique aspects pop up like you heard me talk about earlier, the MSI, right? On a large scale, multibillion dollar project where you’re incorporating multiple different systems onto a network.

You have to have somebody [00:08:00] quarterbacking that effort in the master systems integrator role, right? Each system is going to have its own manufacturer, its own integration team, contracting team that are tasked with that system. But that system is part of a larger system that all has its own different contractors, et cetera.

So, if you don’t have someone in a role as a master systems integrator, understanding how all these systems are supposed to work in concert, you’re setting yourself up in a position to fail and the commissioning team rolls right in to work in concert with the MSI, right? If the MSI is tasked with understanding the holistic view of how a system is supposed to operate or interoperate with other systems, the commissioning team fits right in there in assisting with development of use cases and all the metrics necessary to make sure it works properly.

Andrew Martin: Yeah, that’s really interesting. So, in these situations where you have new systems and that need to operate and work at the scale and with the interconnectedness that you’re describing, if there isn’t any history of the technology in [00:09:00] general or of this system specifically, from a certain manufacturer, how do you even approach the design and the testing, developing test procedures and how you’re going to go about validating that it works.

How does that look if you just consider or compare that to, a technology that’s been around and there’s plenty of history and there’s plenty of standards and best practices?

Christopher Fasano: It’s a fantastic question. And there actually is a methodology that we use that is slowly, but surely catching on with a lot of aviation clients, but we’re hoping, stretches out to other areas of the engineering industry. And that is the implementation of what we call a test laboratory, right? If you look at an example of a large scale, multibillion dollar infrastructure upgrade for an airport What a lot of clients are doing now through either their design build team or, the team contracted to perform the work is they are requiring the implementation of a test lab.

Now, this can be on site. In a lot of cases, [00:10:00] it’s off site where the project team builds a test laboratory somewhere in close proximity to the client. And within that test laboratory, you’re basically setting up a mock virtualized and physical environment, right? So, you set up a small data center with data racks.

You have floor space to bring in pieces of equipment. Like you can bring in part of the self bag drop system. Basically, you are building a test environment with the exact equipment that you’re going to be utilizing in the field, right? In a downscaled version, right? So, for a self bag drop system, you may have, a few thousand pieces of equipment, multiple, bag drop pieces of equipment, you’ll bring one in and you’ll basically build a system with all the parts and necessary integrations that you need within the lab to prove the function of it within that lab space before, sometimes before construction even starts, right?

To validate the process within [00:11:00] that virtual environment, build as much of it as you can within that test laboratory, and then during construction, it just becomes a process of lifting and shifting the things you’ve built in the laboratory into the field.

And that is critical for especially the new systems, right? Because a lot of these aviation clients are using similar products and manufacturers, et cetera. And I’ve got an example right now. I’m not going to mention any names. We’ve got an example right now, where one airport on the west coast is utilizing a system that another one of our clients on the east coast is going to be implementing 2 years from now.

And we are flushing out all of the issues with this similar system. through a test laboratory with that one client, right? Now, hopefully the next time you do it, you’ve learned from all your mistakes and you can implement it better, but you can’t wait until the equipment is installed and integrated on site to find out if it works or not.

You have to be setting up procedures both [00:12:00] physical and virtual to test and validate that these systems, specialty systems, work the way they’re intended to before it becomes critical to the timeline and critical path of the schedule.

Andrew Martin: Yeah, that’s definitely a very rigorous approach it sounds and this is different than what a lot of us know as factory acceptance testing.

This is not just the vendor saying, okay we, we tested it with the software that we’re going to use on this project. This is literally building the system first before you build it permanently on the project, building it first in the laboratory. Okay.

Christopher Fasano: This kind of happens in between factory acceptance testing and the final integrated systems testing that would happen, right?

So, factory acceptance testing happens with the manufacturer validates that their equipment and system works properly. Then we take it and we build it within the laboratory integrated with other systems that have also gone through FAT’s as well [00:13:00] and build a mock up, if you will, of the integrated systems in the way they’re supposed to work to test them.

So yes, it is in fact the different than factory acceptance testing. It’s more robust and it’s the next level.

Andrew Martin: Got it. So, In North America, at least with what I’m familiar with, there aren’t a lot of airports that are being built as new airports, like ground up the Greenfield airport.

It’s usually expanding an existing airport. So, all of these complexities we’re talking about, it must just get exponentially more complicated when we’re talking about tying into existing systems and old versions of systems and software and infrastructure. Is that a, is that an accurate assessment?

Is that how most projects go and are There are additional complexities that get thrown into the mix because of this.

Christopher Fasano: Absolutely. And not much different than, when you face this with any industry, you look at a lot of enabling efforts up front that are associated with, discovery.

Site [00:14:00] surveys, et cetera, of all the existing elements, right? What you’re tying into at times, clients try to isolate their new facilities if they’re building a new terminal, they will attempt in some way, especially if they’re, if they’re making a major upgrade from their legacy systems.

They will try to isolate what they can while building in the scalability to go back through their capital development plan and understand, okay, can we connect to the existing systems? If so, in what capacity, if not, what is the capital development plan to ultimately upgrade those systems?

And can we make sure we’re building in capacity? And the strategic elements, especially within the network, right? You have to have scalability oftentimes, you have to build converged or hyper converged environments that allow you to scale an upgrade as you go, but yeah, we’re constantly up against understanding what a client has existing.

What your responsibility is as a whole to tie into those systems. Bring those [00:15:00] systems on board in the new facility as well. So, yes, it’s just another added layer of complexity where, I will say this as a firm. Faith Group itself has its own test laboratory here within our headquarters, right?

So, aside from relying on clients to build their own test laboratories, we’re able to do a lot of that stuff in house ourselves where we’ve got, vendors and manufacturers constantly bringing new technology into our lab space. So, we can understand how it interacts with their existing equipment and systems, how we onboard legacy systems, can we implement a system overlay that at least is pulling information from legacy systems so that it can be incorporated into the data.

There’s a whole, I won’t get into this too much because it’s a whole another discussion, but when you’re looking at the network itself. Oftentimes you have to understand how a client is managing their data.

Do they have a data lake where they’re pulling in all of their systems? Can it be managed through some sort [00:16:00] of analytics measure, etc. But yeah, a lot of projects miss the Requirement or the amount of time and effort that needs to go into the overall network development, right?

Aside from the physical pieces of equipment and, items that you’re implementing on a project, you have a whole network piece of how you pull all this information together, how you utilize that information. So, with all that, I was just bored in the idea of if commissioning is necessary anywhere, it’s got to be here.

You’re essentially dealing with a small-scale data center, that’s managing so much data points, information, et cetera. You have to commission that. You have to make sure it works properly.

Andrew Martin: Yeah. That sounds like quite the effort to make sure all of that is happening correctly and all of the stakeholders and in an airport project there are additional stakeholders beyond what we might be used to in a commercial building where of [00:17:00] course, there’s always some level of regulatory requirements to build a facility, open it, but with an airport there, there must be more, right? So, what are some of these additional regulatory requirements and parties and stakeholders that you’re dealing with in an airport?

Christopher Fasano: Yeah, oftentimes you have to keep in mind that these aviation facilities oftentimes operate as critical operations power systems and emergency operations centers for the cities that they’re in. We have clients that within their airport facility have, an EOC and an SOC, a security operations center, emergency operations center.

Oftentimes they have a 911 call center within their emergency operations center where they can field 911 calls, where they can field emergency operation calls, etc. Aside from some of the other unique stakeholders, like vendors transportation security administration et cetera.

Oftentimes cities rely on their aviation [00:18:00] hubs to act as the emergency and security operations center. So, you have to bring in information from, local police departments, fire departments, 911 call centers all of these different stakeholders that have a stake in the operation of this facility that oftentimes, is a critical operations power system that has to stay up and running 24/7, has to have emergency power backup et cetera.

But we have to remember that the airport is not simply just a place where people go to fly out, right? It’s a major security and emergency hub for a lot of cities that they’re present in. So yeah, there’s multiple stakeholders involved that sometimes we don’t even think about being involved in the process.

Andrew Martin: Yeah, now that’s really interesting. So, if an airport is considered in a lot of ways, critical. Infrastructure in cities and states and society in general. There must be huge implications for what that means for. [00:19:00] Cybersecurity physical security, obviously, if we’re talking about cybersecurity and networks, this isn’t like a department store where you just have a network and you connect the building automation system there, all the POS systems are connected there.

That’s where the guest Wi-Fi is running off of. Can you talk a little bit about, that’s probably a whole discussion in itself, but is there a way to summarize some of the differences and how you think about network design and cyber security in an airport versus a more traditional commercial facility?

Christopher Fasano: Sure, absolutely and it’s important for me to say there’s a whole group of individuals way smarter than me and way more adept when it comes to the cyber elements, right? We have a whole cyber security division here at Faith Group that is currently working on multiple different major hub projects that include things like Wi-Fi, cybersecurity, et cetera.

But yes, to the point you make with the criticality of some of these facilities, there are always multiple different [00:20:00] requirements on how they operate and what they’re allowed to do. We think about things like physical hosting structures versus cloud-based hosting structures, right?

How information is shared or stored within the airports, IT network division. So having a network design and architecture team on board to understand, what type of network we’re building, whether it’s a fully converged network, we’re implementing some hyper converged networks in locations where we’re allowed, the network itself is allowed to track and manage information and data from multiple systems, whether it’s AV, telecom, security, et cetera. All in a, whether it be a localized physical hosting structure or a cloud-based hosting structure. And these are things that within the commissioning world we’ve had to become very creative about how we test the cyber security of a system, right?

And ultimately, it always comes down to the same thing in commissioning, right? It’s the use case, right? We need to understand how the system is intended [00:21:00] to work. Understanding how the system is intended to work, then we can simulate measures in an attempt to test if the system actually works that way and I think, that’s one of the elements that within the aviation world has really kicked off is that commissioning is no longer just commissioning, right? It is commissioning, its activation, and its simulation, right? So, we can’t just commission systems, we have to activate those systems, right?

Prepare the team members that are going to operate those systems, to be able to operate those systems. And then we have to simulate measures, right? So, in the physical world, it can be easy, right? If we’re bringing on a common use terminal and it’s, 10 days before opening day, we can simulate the use of that terminal.

We can get. 600 volunteers to walk into the terminal all with boarding passes and figure out how it works. But within the cybersecurity world or this virtualized environment, we often have to become very creative with how we attempt to test these systems, right?

If there’s [00:22:00] infiltration measures based off local IP addresses, but we have to simulate an environment where a request is coming in, from a non-local IP address and ensure that the system reacts the way it’s supposed to, and then determine clear validation of, okay, when this happens, what do we expect to see?

So that when we try to infiltrate the system, with an email from an off IP address is it tagged within the system that it’s outside of the boundary? It’s a whole another element of commissioning where the principles are essentially the same. Tell me how it works, right?

Describe it in detail and then test it in whatever way you can to make sure that the things that are supposed to happen, happen.

Andrew Martin: Yeah. It sounds intense.

Christopher Fasano: It’s again, it’s people way smarter than me figuring this out. It’s a world that I’m only beginning to dip my toes in, but as a firm, we’ve got those individuals that know this stuff and are able to go out and test it.

Andrew Martin: Yeah, no, that’s great. To bounce back to something else you [00:23:00] mentioned, just as an example, self-bagging or, a passenger bagging system, self-tagging systems. I’m not sure what the right term is, but just as an example of something that’s newer that airports are starting to adopt and want to implement.

Are there other trends that you guys are seeing or other technologies that you guys are seeing airports experimenting with or talking about or things they want to be able to do that are maybe just a little bit over the horizon right now? Can you just talk about some of that stuff and what, people might expect to see walking through airports in the next few years or five years, whatever it might be?

Christopher Fasano: Sure. So, there’s way too many things to list, honestly. The airports are doing a lot of wildly different things. LIDAR, for instance, which is an old school technology, is being implemented in ways that can track data movements, et cetera, to do different data analytics measures that can be tied in with a lot of other security measures, right?

Gunshot detection is one, right? If you have a gunshot detection system, it detects a gunshot. Can you [00:24:00] use your LIDAR system to track the movement of people? So, you see if a thousand people are running in one direction and one person is running in the opposite direction. Can you use data analytics to try and derive what the scenario is and what’s happening, right?

Thrown object detection for TSA. It can actually track and monitor if an object gets thrown over a barrier, right? And these are some of the more, exotic security measures, but in ways that people will see there’s a lot to it. The big one that comes to mind is wayfinding. When an individual steps into the airport, what is the information that they’re fed that allows them to navigate through the airport?

And how does that information interact with them? Facial recognition and retinal scanners are a big one, right? Can we tie the same way Netflix and Facebook target ads towards you through your phone and your computer, right? Can we pull information back from the individuals who are at the airport and be able to feed them information that they need.

In a future world, I [00:25:00] should be able to walk up to an information display system, it should recognize who I am and feed me, here’s your flight, here’s what gate it’s leaving from, here’s how you get there hey, it’s lunchtime, if you’re hungry, here’s some places to eat. It sounds wild, sounds a little Big Brother ish and invasive but, this is already information that we’re utilizing within the industry, right?

And being able to provide, a better environment for a better, safer easier to navigate environment for individuals is the direction that a lot of these aviation clients are heading. And the audio-visual aspect of it is a lot of times in your face and that’s how we satisfy the needs of clients by understanding who they are, what they need and feeding them that information.

Andrew Martin: Got it, that’s really interesting stuff. And I could have prefaced, asked the question slightly differently. Cause I asked what people would see walking through an airport, which is really interesting, and the stuff we tend to draw our attention to, but there’s so much that’s happening [00:26:00] under the covers and behind the scenes that probably just vastly more than what we actually see.

And if all of that stuff is working well, it’s stuff we don’t know about cause it’s doing its job and keeping, keeping things moving and people safe.

Christopher Fasano: That’s exactly it.

Andrew Martin: Okay. So, just to wrap things up here to talk a little bit about how an airport project gets to the end of the process you’re getting through commissioning and final commissioning or functional testing, integrated systems testing, and you’re getting to the point where the project will be handed over to, the entities that are going to operate the facility. How does that process look for an airport versus again, comparing to a typical commercial project or there is the facilities operations staff structured similarly in an airport, who all is being trained and what type of information gets handed over, how does it get handed over? [00:27:00]

What does that process look like?

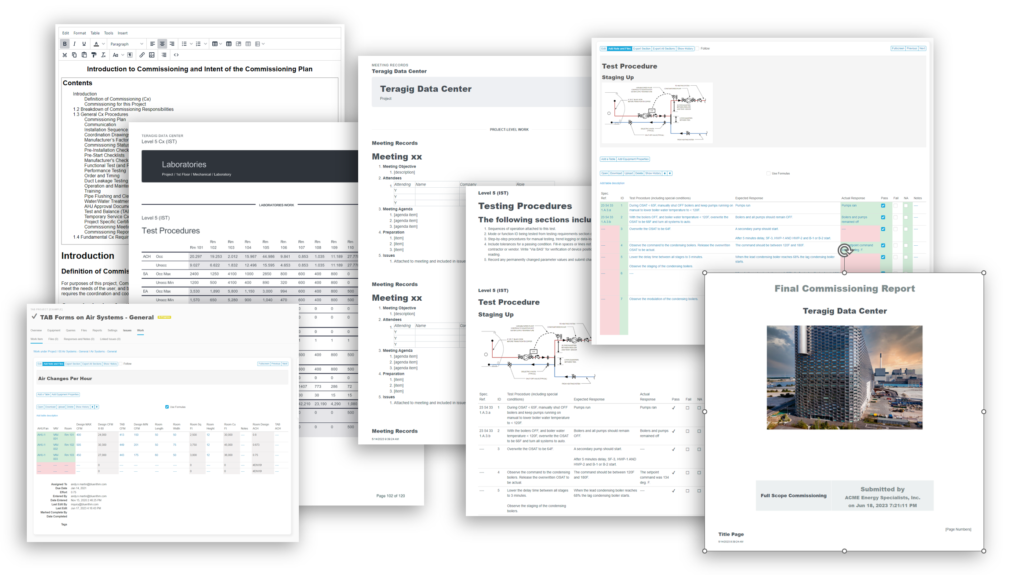

Christopher Fasano: Sure. So, this is one of the areas where we start to talk about, technology solutions, right? What are we utilizing as a team in order to disseminate all of the valuable information to stakeholders, operators, et cetera logically, the process needs to start, at the advent of the work, right?

With the stakeholder involvement, understanding what they need so that we are not waiting to the end stage of the process to train these individuals, feed them the information that they need. And the big thing, when you look at whether these are privately funded P3 projects, et cetera people want information.

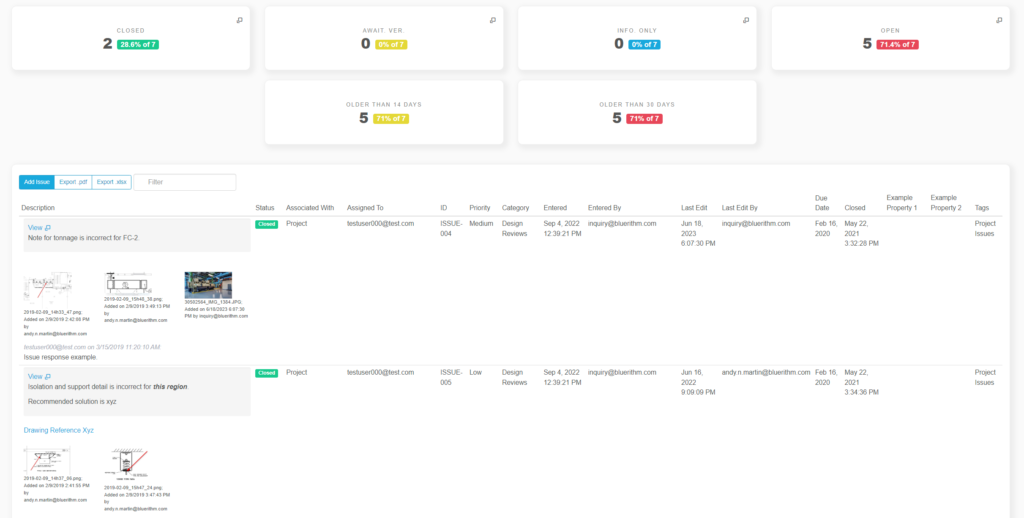

It’s in the public eye and the individuals working on the project, the ones that need to be trained, they need a tremendous amount of transparency into the process, right? Within the industry, a lot of times we call it traceability, right? How traceable is all of the [00:28:00] information that I need on the timeline, whether it’s for a specific piece of equipment or a system as a whole, how do I, as a stakeholder or the owner or whoever, get as much insight into what’s going on?

Because that is where the training process begins, right? If a stakeholder understands the process from start to finish, all the steps that it went through, everything that’s required, that already is training them up on how the system works because they need to weigh in on questions and operating standards, et cetera.

And when you’re talking about, hopefully everyone understands the complexity at this point, right? When you’re talking about that level of complexity, thousands and thousands of integrations and systems working together, no one person or even team of people can keep track of that logically.

You need a system, a technology that’s able to aggregate all of that information and keep it in a single source of truth where everybody can access it and [00:29:00] understand clearly what’s happening, where are we? Can I trace something through its entire process? Do I have the information that’s readily available to me to understand what’s going on?

So that as we get to this end stage, and hopefully to answer your question, as we try to make a facility operationally ready, it has to stand on the foundation of the information that’s available to the people that are going to be taking over that building. And if you can set up a project in a way where throughout the life cycle of design, construction, even before that, we’re talking about concept of operations, schematic, et cetera.

If you set up a process through that life cycle that allows the stakeholders insight visibility and traceability over every aspect that we touch, then that helps set them up for success. So that when you get to the end stage yes, you still have to go through your specific training, end user training, et [00:30:00] cetera, to get people physically up to speed on how a system works.

But hopefully by that time, they’ve already seen the life cycle of this piece of equipment. Come on board, come to life so that they have a deep, intimate understanding of what it does, how it does it. So that training is that end stage of, okay, now that it’s here and physically on site, here’s the buttons you push.

Here’s how it operates. There are many different elements that go into operational readiness and training of airport staff. But for me, the most important part is that the stakeholders have as much visibility as we can logically provide to them so that we fully understand what they’re taking over at go live.

Andrew Martin: Yeah, that’s great. That’s great. Good stuff. So, this was a pretty rapid-fire session. A lot of information. I’m sure there’s a whole discussion in any one of these topics that we touched on today. [00:31:00] So if people want to get in touch with you and talk more about this stuff, where’s the best place to do that?

Christopher Fasano: Email’s probably the best. [email protected], we also just spun up the latest revision of our website, which is really slick. So faithgroupllc.com is another place you can go to get in touch with us. I’m from an aviation commissioning standpoint, I’m always available to talk to anybody that needs information.

So, email’s best.

Andrew Martin: Excellent. That’s great. I really appreciate the conversation today. Hopefully everyone else does as well. Really good stuff. So, thanks, Chris. And we’ll talk to you again soon.

Christopher Fasano: Yeah. Thanks, Andrew. Take care.