The conflicting forces of higher quality, lower cost, faster delivery…and a pandemic

Progress begets progress. We will never reach a time when society says, “Ok, that’s good enough” and quits innovating and dreaming. It’s antithetical to human nature. Because we can, we will!

Even though the property design & construction industry has lagged a bit in shaking off decades of productivity stagnation, in recent years innovation in project delivery models, standardization and prefabrication of major components and systems are proving that even old, slow moving industries eventually get shaken up by our need for progress.

Data centers are being built in record time. “If you look at how fast these web-based revenue generating companies are going, they absolutely want the product faster,” Tesh Durvasula, European president of data center real estate investment trust said recently. When new methods deliver positive results, we build on them and push the innovation further. In times of high demand and competition, the pace of change and innovation increases at faster rates.

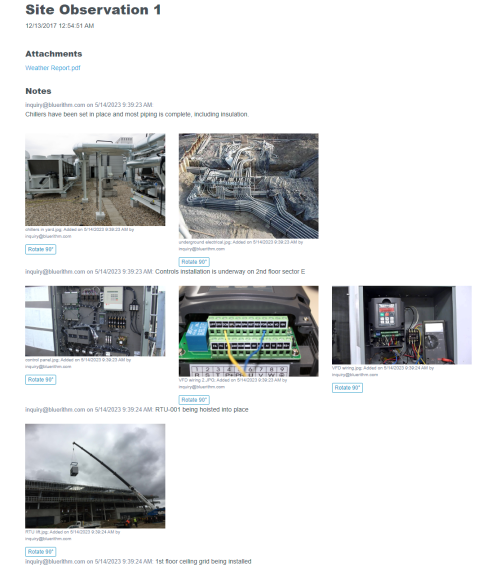

Prefabrication is allowing standardized systems and components to be assembled and tested in controlled manufacturing environments, then shipped to project sites ready for installation as modular parts. This can improve quality and speed. However, owner’s financial imperatives for speed do not give way to the demand for customization of their facilities. So an entirely cookie-cutter large scale data center, for example, is still uncommon.

Streamlined project delivery models like design-build (DB) and integrated project delivery (IPD) are consistently providing higher quality, lower costs, and much faster delivery. Design-build allows asynchronous design and construction activity. Construction of the building envelope and structure can begin while major MEP and interiors design is still in early stages. There are exceptions, but a traditional design-bid-build (DBB) model is synchronous – one phase must finish before the next.

How we think about our facilities has changed

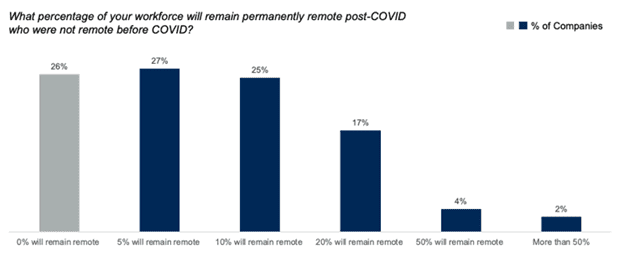

The way we think about our needs for facilities has changed during the coronavirus pandemic of 2020. Some of these changes will be permanent. Industries that traditionally resisted work from home policies were forced to implement and make them work.

The gains in productivity and reduced facilities costs have been natural outcomes of the forced shift to remote work, and many corporations will continue these policies even after it’s been deemed safe to return to pre-pandemic operations. Mike McLaughlin, chief information officer at Technologent recently said “Getting employees to work from home can help cut facilities costs. Real estate is expensive, and maintaining facilities is expensive.” Gartner says about 74% of CFOs surveyed expect some of their employees to continue working remotely after the pandemic ends.

These shifts may reduce the overall demand for the square footage we need, leaving us with more specialized, or in some cases more adaptable and flexible facilities. The reduced demand will help conform to possible mandates or guidelines for lower density.

Office space may incorporate social distancing features in the design of spaces and ergonomics. Even in general commercial spaces, there will be greater emphasis on HVAC solutions for controlling air exchanges, air quality, filtration, etc. similar to healthcare and BSL practices, such as:

- Installing filtration (antimicrobial filters, HEPA), bi-polar ionization and UV lights at return air openings and at components within the air system.

- Implementing pressurization control and/or enhance current practices.

- Increasing airflow (recirculated and outside air).

- Deactivating demand control systems that limit concentration of outside air.

- Operating systems longer and with higher outside air content to flush spaces due to increased use of cleaners.

- Operating ventilation systems serving communal spaces such as toilet rooms continuously (24hours/day), since they have a higher risk of contamination.

- Maintaining minimum relative humidity levels.

- Sanitizing ductwork with aerosol sprays or UV light.

- Using portable air purifiers.

While healthcare facilities are already designed for infection control, logistics, flexibility, the ability to quickly adapt to surges are new areas of focus. A recent survey of the American College of Healthcare Architects (ACHA) members provided insight into how healthcare facility planning and design may change.

- Over 63% of respondents helped clients evaluate alternative care sites.

- Over 60% of ACHA experts were called on to help healthcare systems increase capacity – 28% created over 100 beds.

- Over 70% of respondents believe design for mass casualty patient surges will be an important element for hospitals in the future.

- Over 80% of respondents thought the telehealth boom would have major impact on facility design.

The more collaborative and flexible IPD and DB contracting models will also become more common purely from the standpoint of allowing fluid response to uncertainties, like new waves of COVID-19 or other disruptions. These models don’t just deliver speed and cost savings; they can be more flexible to adapt to abrupt shutdowns or slowdowns while avoiding major contractual issues.

What about this recession?

On top of these other forces, we’ll be dealing with a recession for at least the immediate future. There are predictions across the spectrum for how long recovery will take from credible economists, but that the impact of the pandemic was severe is indisputable. What we also know is that recovery will happen, and we have to prepare for that time.

Many businesses failed during the recession of 2007-2009. Federal data shows over 170,000 small business in the United States closed their doors. In 2010 HBR reported over 17% of business in general had already “went bankrupt, were acquired, or became private.” But there were exceptions – some companies not only survived but expanded.

Companies that started slashing costs more aggressively than competitors had the LOWEST probability of pulling ahead once the economy turned around. On the flip side, only 26% of companies that invested aggressively did better than rivals.

The companies that had the greatest probability of not only surviving, but pulling ahead of the market after recessions were the ones that found a balance between strategic cost saving measures in operational efficiency, and investments in the future.

The more dynamic the economic environment, whether it’s due to geo-politics, climate, or pandemics, etc., the more fluid and adaptable our companies must be.

After all, when we take a step back, even the darkest periods in modern history become blips in the economic story.

What does this all mean for your commissioning firm?

Progress is what moves us forward, but it also brings challenges and growing pains.

We’ve been reminded that change, whether along predictable curves or due to unforeseen global events, is something we need to be ready for.

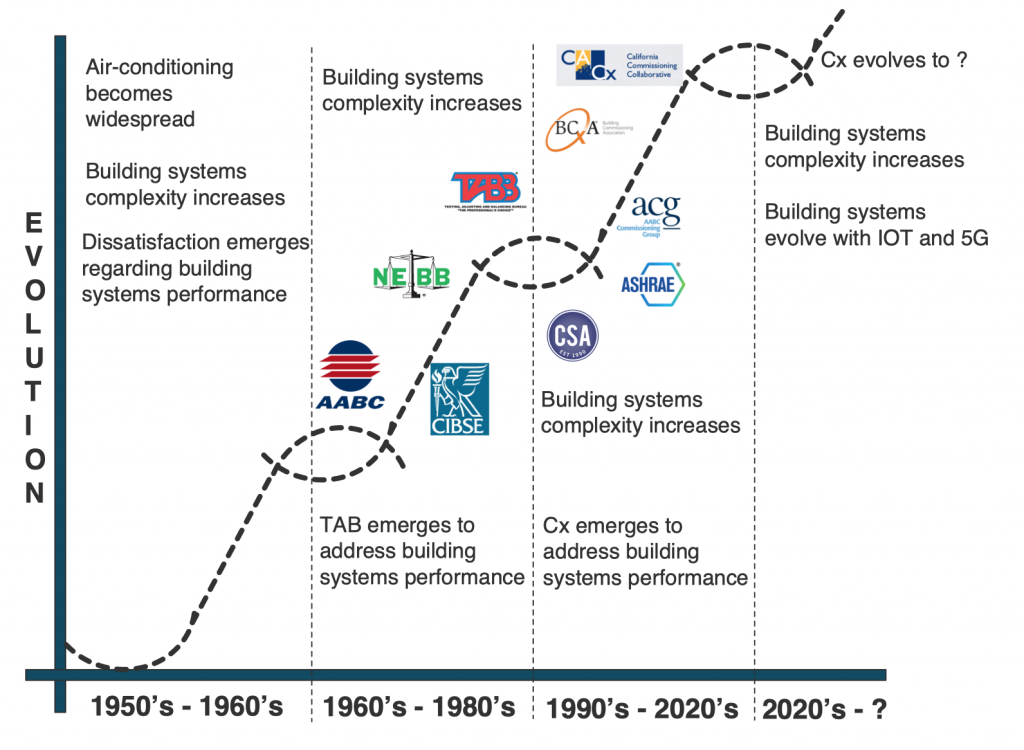

Risk rises as complexity increases. The more complex the buildings, cities, systems, contracting models, and economic environments, the more vulnerable the ‘human element’ becomes.

While prefabrication can contribute to speed and standardization, the overall complexity of buildings and systems will rise as we reach for higher levels of energy efficiency, safety, reliability, cleanliness, and comfort.

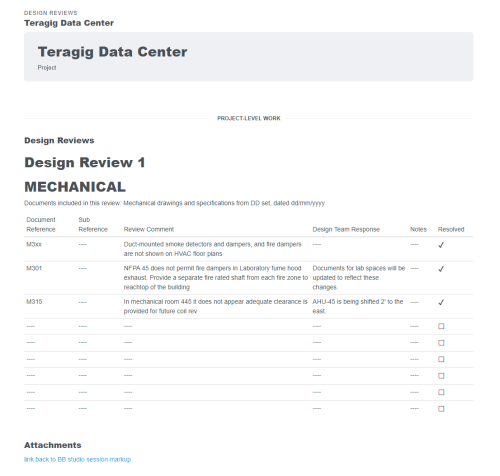

Integrated project delivery and design-build models come with challenges that don’t exist in traditional design-bid-build models. A DBB model has inherent checks and balances and checkpoints built into it. In an IPD or DB model, the design and contracting team are one and the same. This requires a high level of owner-involvement and expertise to manage effectively, and to receive a final product that suits their original intent. Many owners do not have the experience or time to manage a fast moving IPD or DB project.

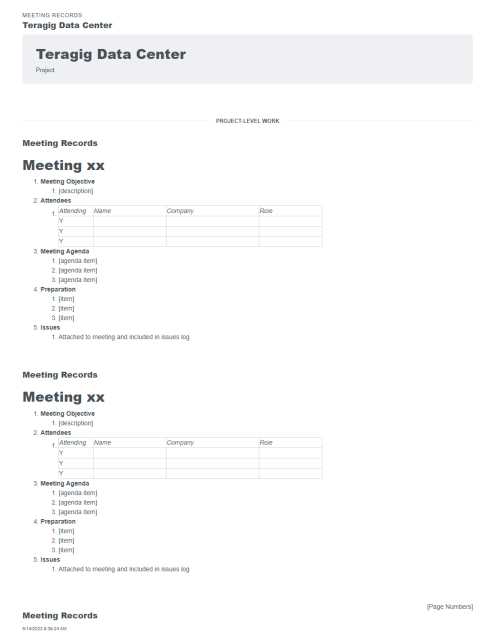

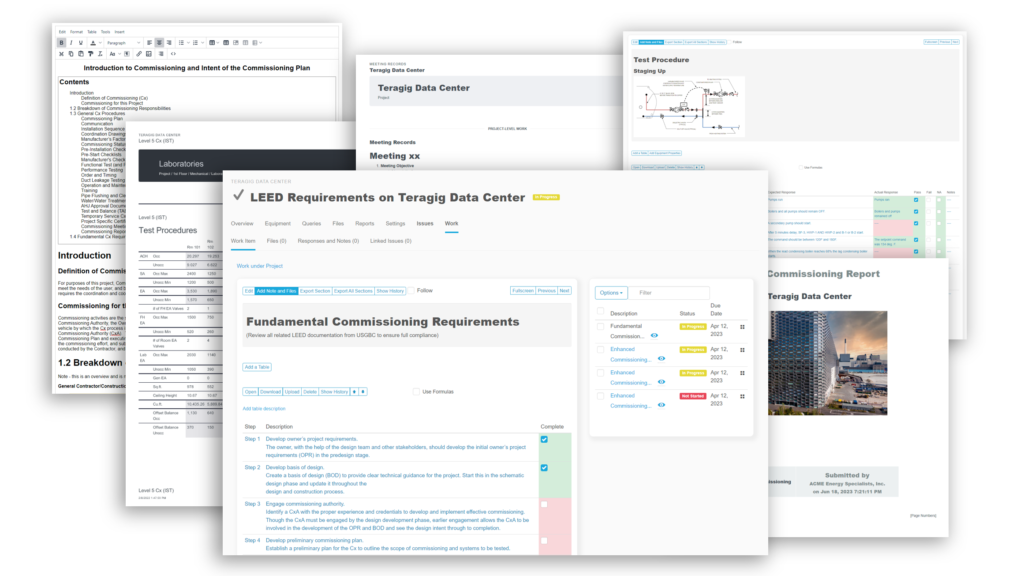

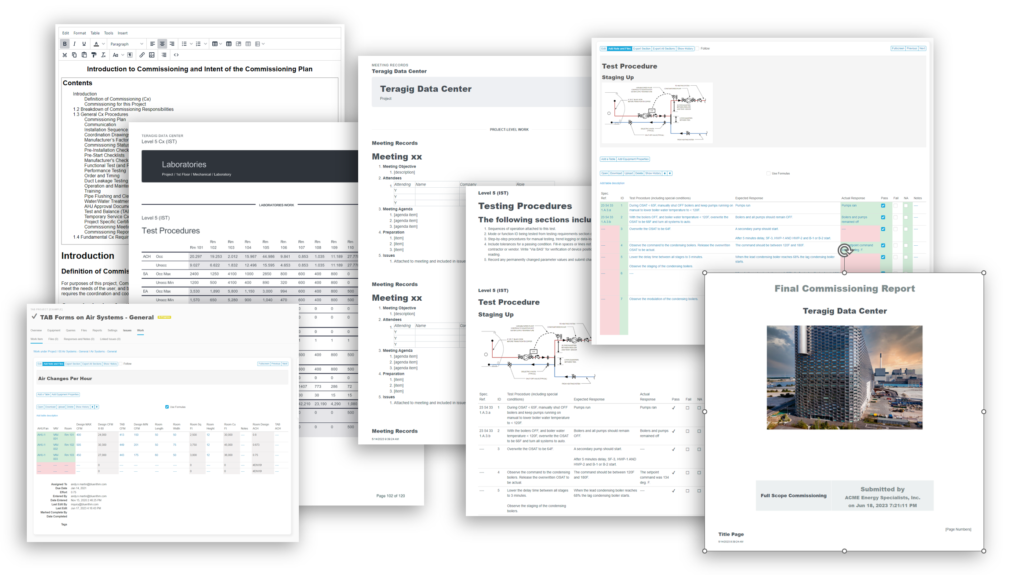

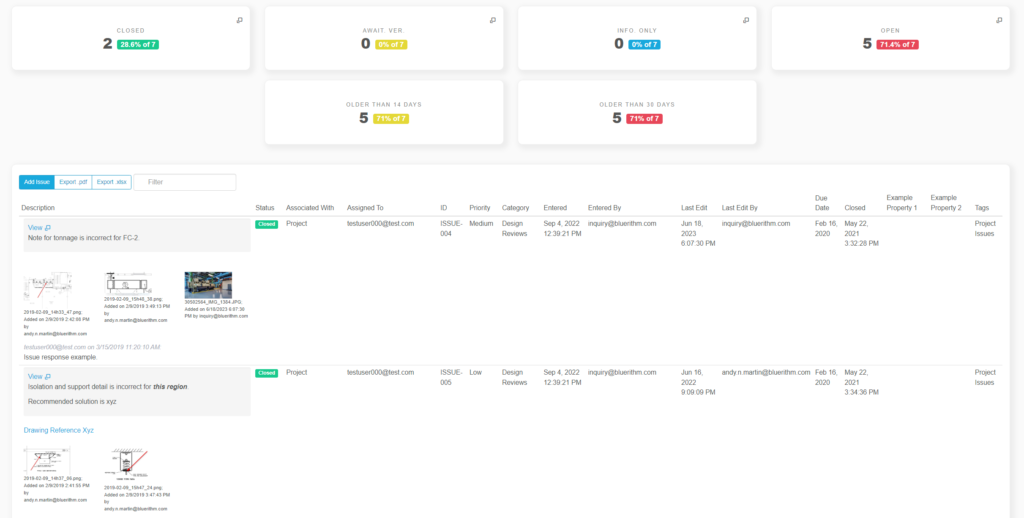

We believe a robust commissioning program is key to addressing the added risks stemming from this increasing complexity, uncertainty, expectations for speed, and these more fluid contracting models. As an independent advocate for the owner, a strong commissioning firm brings experience and expertise that spans across the design and construction teams beginning in the design phase, and continues through integrated systems testing and turnover to the owner.

In the chart above, Adam Muggleton illustrates how commissioning emerged to address increasing uncertainty and complexity in buildings over the past 3 decades. Commissioning as a practice is well positioned to be a large part of the solution to the challenges outlined in this article. The next generation of commissioning providers will need to forge a path towards effectively addressing them.

We hope we have made the case that the days of inefficient and antiquated ways of operating our businesses are numbered. We think the following things are necessary to thrive in our new age:

- Understand all of these forces at work in our industry that contribute to risk and uncertainty, and adapt to be part of the solution.

- Create a culture of learning where your team can stay on top of the state of technology and science around buildings.

- Get serious about creating repeatable processes and standardization within your firm.

- Automate as much as possible, and generally be ruthless about efficiency.

- Have pivot plans ready for when market conditions abruptly change (i.e. a shift to retro-Cx, new verticals, etc.).

- Always focus on quality.

Original content from BlueRithm, where our mission is to streamline mission critical and commercial commissioning projects.

Related: Life Must Go On: Be Ready